Length: 2.44m; 3m; 5m; customized

Skin aluminum thickness: 0.06-0.5mm

Thickness: 2-6mm

Coating: PE coating; PVDF coating

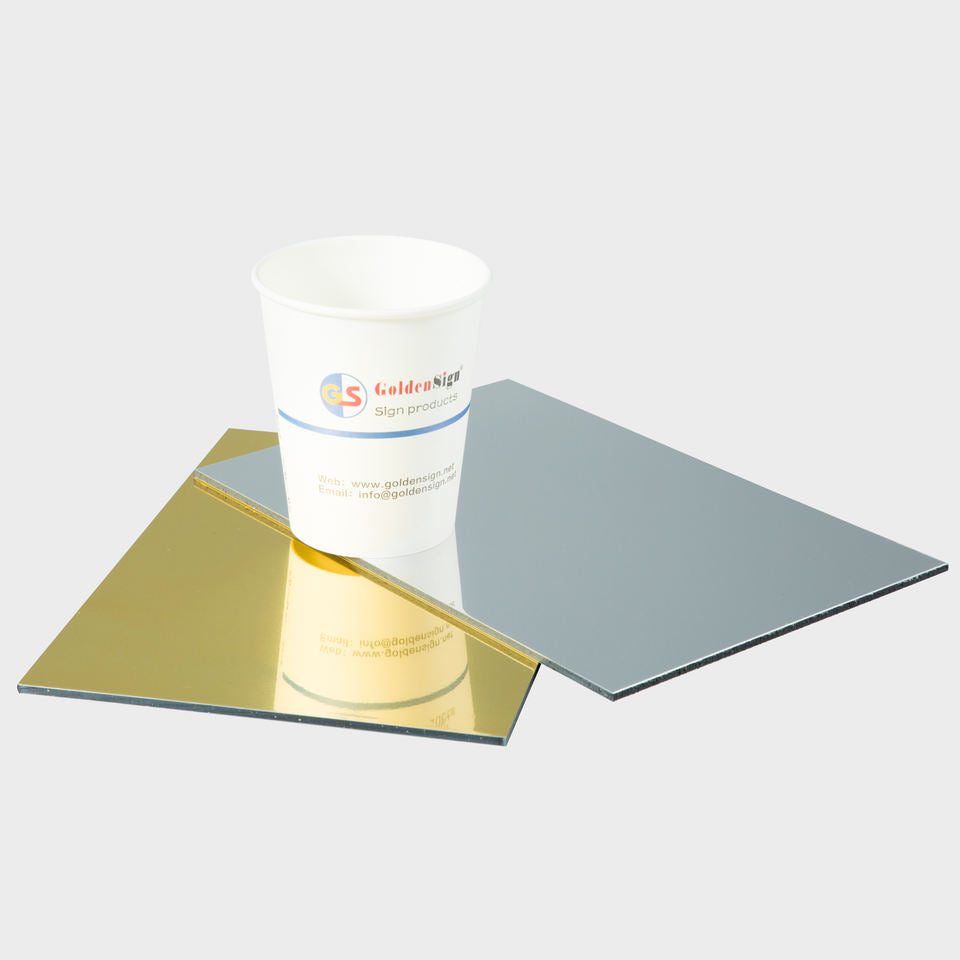

Color: Common; wooden; marble; mirror colors

***Please negotiate with the buyer to confirm the detailed specifications before placing an order, all styles can be customized

***The price is not the final transaction price

Get a Free Quote

|

Aluminium alloy

|

1100, 3003, 5005

|

|

Pencil hardness

|

2H

|

|

Toughness of coating

|

2T

|

|

Elongation

|

5%

|

|

Tensile strength

|

130 Mpa

|

|

Temperature Resistance

|

-50°C to +90°C

|

|

Impact Strength

|

50kg/cm2 , no change

|

|

Boiling water resistance

|

Boiling for 2 hrs, no change

|

|

Thermal Expansion

|

2.4mm/m at 100°C Temp difference

|

|

Acid Resistance

|

Immersed in 2% HC1 for 24 hrs, no change

|

|

Alkali Resistance

|

Immersed in 2% NaOH for 24 hrs, no change

|

|

Cleaning Resistance

|

Cleaned 1000 times with water, no change

|

|

Oil Resistance

|

Immersed in 20# engine oil for 24 hrs, no change

|

|

Solvent Resistance

|

Cleaned 100 times with dimethylbenzene, no change

|

|

Skyrainbow ACP Tolerance(mm) :

|

|

|

Thickness

|

± 0.2

|

|

Width

|

± 2

|

|

Length

|

± 4

|

|

Diagonal

|

± 5

|